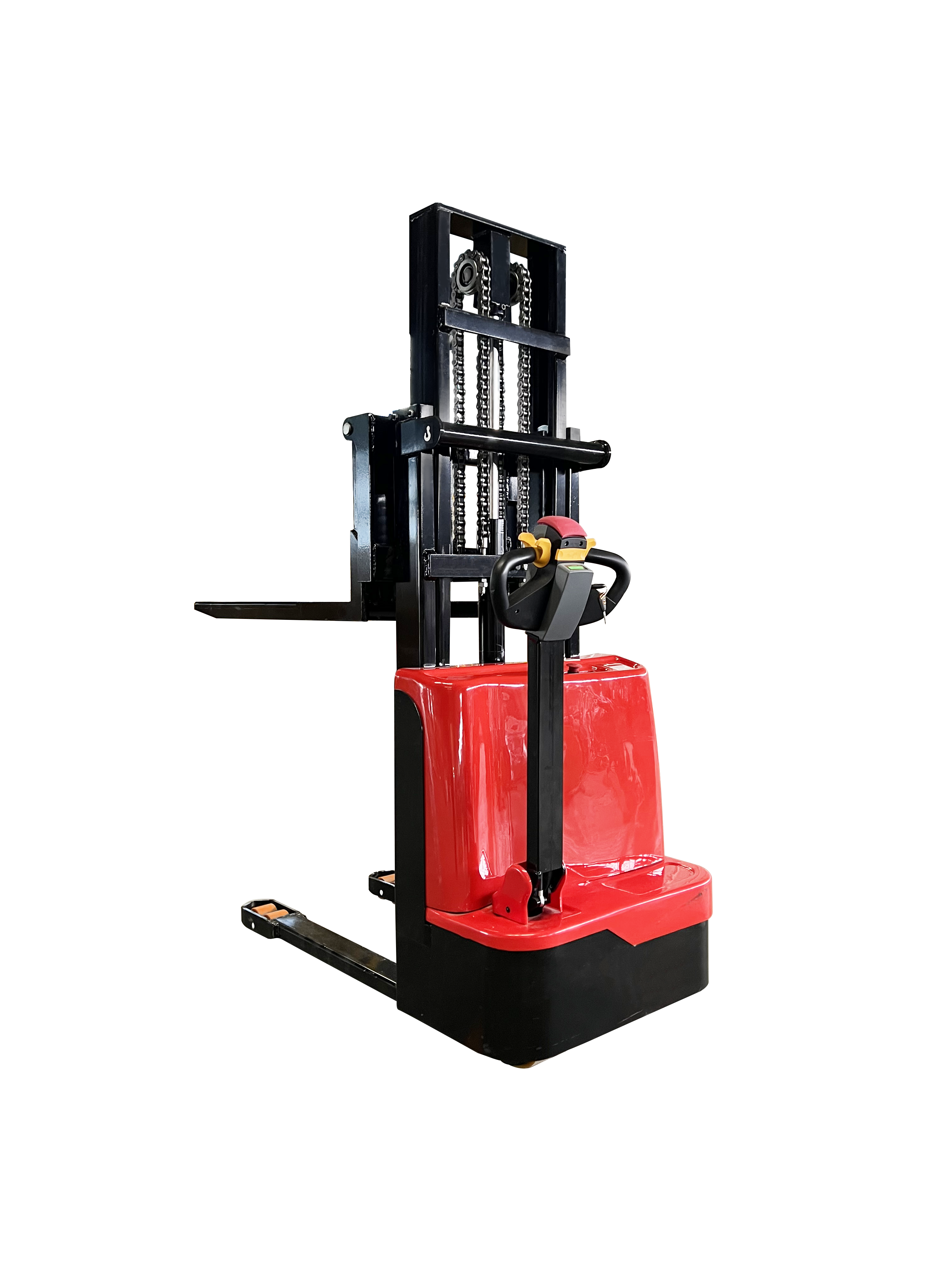

A warehouse stacker is a vital material handling equipment designed to lift, transport, and stack palletized goods within warehouse environments, playing a crucial role in optimizing storage space, streamlining operations, and improving overall productivity. This versatile tool comes in various configurations, including manual, hydraulic, and electric models, each tailored to different warehouse sizes, load capacities, and operational demands. Whether used in small retail backrooms or large distribution centers, a warehouse stacker is engineered to navigate narrow aisles, handle diverse load types, and maximize vertical storage—key factors in modern warehousing where space efficiency is paramount. The primary function of a warehouse stacker is to enable vertical stacking of pallets, which significantly increases storage capacity. By lifting pallets to heights ranging from 2 meters to 6 meters, it allows warehouses to utilize the full height of their racks, reducing the need for expansive floor space and lowering facility costs. This vertical storage capability is especially valuable in urban warehouses or facilities with limited square footage, where land is expensive. Unlike forklifts, which are designed for heavy-duty lifting and outdoor use, warehouse stackers are compact and focused on indoor, pallet-specific tasks, making them more agile in tight spaces and more cost-effective for light to medium-duty applications. Warehouse stackers are available in three main types, each with distinct features. Manual stackers require operator effort to pump a lever and lift the forks, making them suitable for light loads (up to 1,500 kg) and low-volume operations, such as small retail warehouses. They are affordable and require minimal maintenance but can cause operator fatigue during extended use. Hydraulic stackers use a hydraulic system—either manual or powered by an electric motor—to lift heavier loads (up to 2,500 kg) with less effort, balancing cost and efficiency for medium-volume warehouses. Electric stackers, powered by rechargeable batteries, are the most advanced, offering effortless lifting and movement for heavy loads (up to 3,000 kg) and high-volume operations. They feature electric motors for both lifting and propulsion, reducing operator fatigue and increasing productivity, making them ideal for large distribution centers and e-commerce fulfillment hubs. The design of a warehouse stacker includes several key components that enhance its functionality. The forks, made of high-strength steel, slide under pallets and are adjustable in width on many models to accommodate different pallet sizes, from standard 1200x1000mm pallets to smaller or larger custom sizes. The mast, which supports the forks, is constructed from durable steel and features rollers or guides for smooth vertical movement. The base provides stability, with some models including counterweights to prevent tipping when lifting heavy loads to maximum heights. Many warehouse stackers are equipped with wheels or casters, with polyurethane tires for smooth operation on concrete floors and swivel front wheels for tight turning, ensuring maneuverability in narrow aisles. Safety is a critical aspect of warehouse stacker design, with features that protect operators, goods, and the warehouse environment. Overload protection systems prevent the stacker from lifting loads exceeding its rated capacity, reducing the risk of structural damage or tip-overs. Emergency stop buttons allow operators to halt all movement immediately in case of an emergency. Non-slip platforms and ergonomic handles reduce the risk of slips and falls, while clear visibility from the operator’s position ensures that obstacles or other personnel are easily seen. Some electric models include proximity sensors that alert operators to nearby objects, further enhancing safety in busy warehouses. The versatility of a warehouse stacker extends beyond basic stacking and transport. Many models can be equipped with attachments to handle specific load types, such as drum clamps for barrels, platform extensions for oversized items, or rotators for dumping materials. This adaptability makes them suitable for a wide range of industries, including food and beverage (for handling pallets of canned goods or bottles), pharmaceuticals (for moving sensitive medical supplies), and manufacturing (for transporting raw materials and finished products). In cold storage warehouses, specially designed stackers with cold-resistant batteries and components can operate reliably at temperatures as low as -30°C, ensuring uninterrupted operation in frozen environments. Efficiency is a hallmark of a well-chosen warehouse stacker. By reducing the time and effort required to move and stack pallets, it increases throughput, allowing warehouses to process more orders in less time—a critical factor in e-commerce, where fast order fulfillment is essential. The ability to stack pallets high reduces the number of trips needed to store or retrieve goods, saving time and energy. Electric stackers, in particular, offer consistent performance throughout the day, with lithium-ion batteries providing enough power for a full shift and quick charging during breaks to minimize downtime. This efficiency translates to lower operational costs and higher customer satisfaction, as orders are fulfilled more quickly and accurately. Maintenance requirements for warehouse stackers are relatively low, contributing to their long-term reliability. Manual and hydraulic models require periodic checks of moving parts, lubrication, and hydraulic fluid levels (for hydraulic models). Electric stackers need battery maintenance, such as regular charging and occasional inspections, with lithium-ion batteries requiring no additional upkeep. Cleaning the stacker regularly to remove dirt, debris, and pallet fragments helps prevent rust and ensures smooth operation. Many manufacturers provide maintenance schedules and training to help operators keep the stacker in optimal condition, extending its lifespan and reducing the need for costly repairs. In conclusion, a warehouse stacker is an indispensable tool for modern warehousing, offering a combination of space efficiency, versatility, and productivity that is essential for meeting the demands of today’s supply chains. Whether manual, hydraulic, or electric, it is designed to handle the unique challenges of indoor material handling, from navigating narrow aisles to stacking pallets high. By investing in the right warehouse stacker, businesses can optimize their storage space, reduce operational costs, enhance workplace safety, and improve overall efficiency, making it a key component of successful warehouse operations.