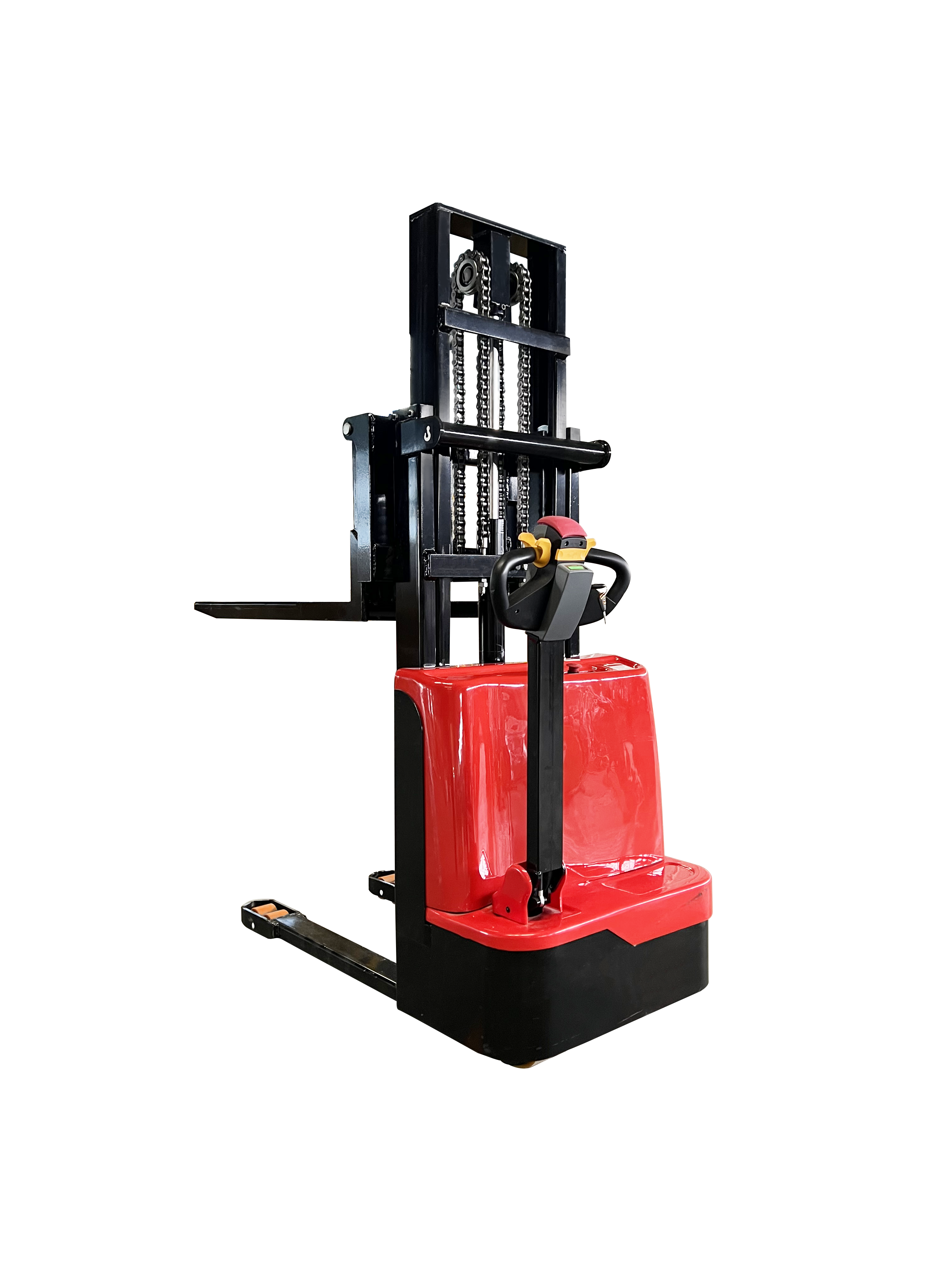

Relilift: Premier Provider of High-Quality Pallet Stackers

Relilift stands as a leading force in the materials handling sector, renowned for its specialized range of forklifts, stackers, and notably, pallet stackers. Our unwavering commitment to excellence is reflected in the superior craftsmanship and innovative design of our products. We cater to a global clientele, meeting the varied demands of logistics, warehousing, and manufacturing industries with precision and reliability. Backed by a team of seasoned professionals, Relilift emphasizes continuous innovation and improvement, ensuring our pallet stackers are not only efficient but also safe and dependable. Our mission is to deliver cost-effective material handling solutions that elevate productivity and streamline operations for customers around the world. Whether you require a pallet stacker for light-duty tasks or heavy-duty applications, Relilift has the expertise and product range to fulfill your needs.

Get A Quote