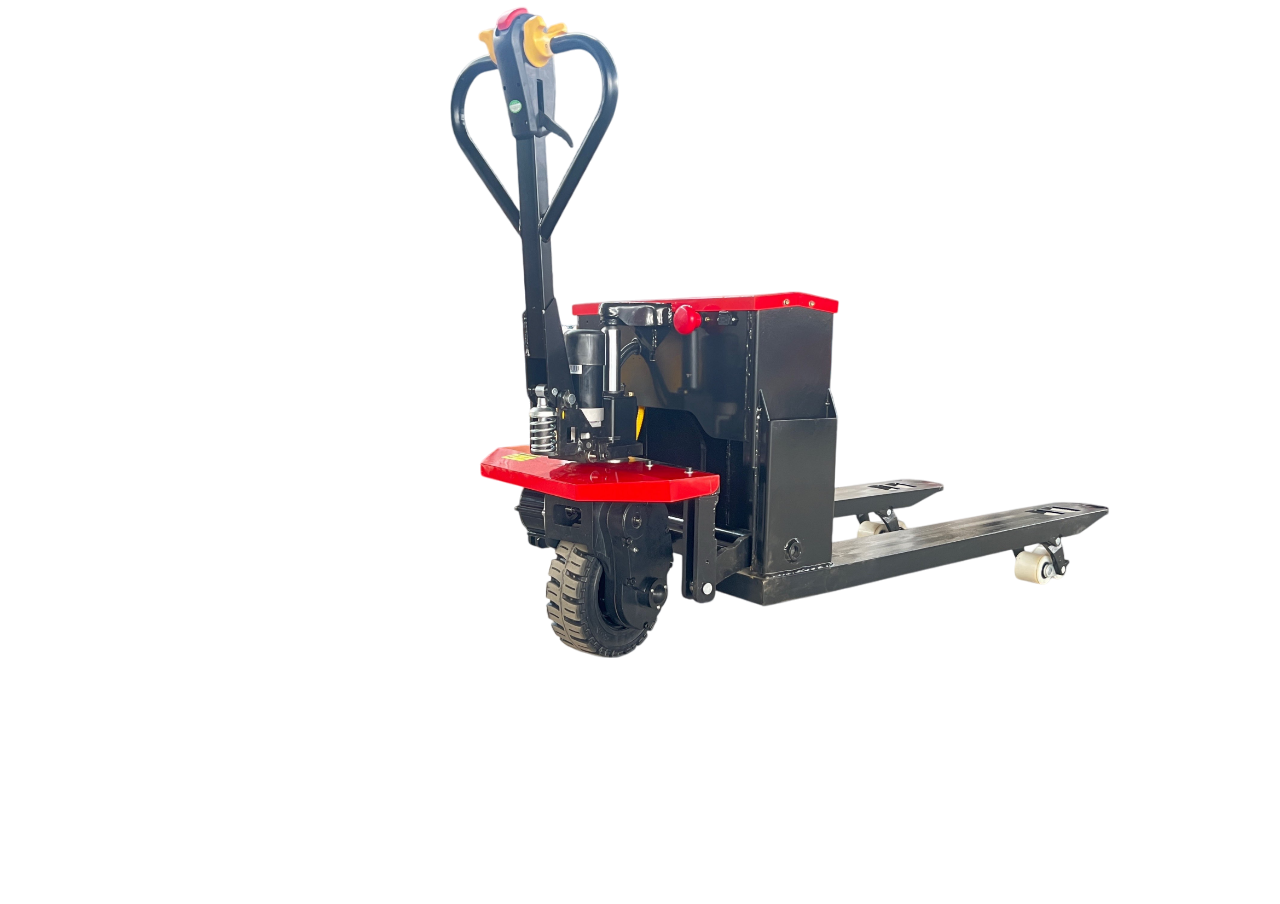

A pallet mover electric is an innovative material handling tool designed to simplify the transportation of palletized goods through electric power, offering a significant improvement over manual pallet movers in terms of efficiency and operator comfort. It is widely used in warehouses, distribution centers, retail stores, and manufacturing facilities, providing a reliable and sustainable solution for moving heavy loads without the need for physical exertion. This equipment is particularly valuable for businesses seeking to reduce labor costs, minimize workplace injuries, and enhance productivity in their daily operations. The design of a pallet mover electric is centered around a robust steel frame that provides the strength to support heavy loads, typically ranging from 1,000 kg to 3,000 kg. The frame is engineered to withstand the rigors of daily use, including frequent movement over concrete floors and occasional impacts with racks or walls. Attached to the frame are two steel forks that slide under pallets to lift and secure them during transport. The forks are designed to fit standard pallet dimensions, but many models offer adjustable widths to accommodate various pallet sizes, from small skids to large industrial pallets, increasing versatility across different applications. The power source of a pallet mover electric is a rechargeable battery, with lithium-ion batteries being the preferred choice for their superior performance. These batteries offer faster charging times, longer runtimes, and a longer overall lifespan compared to traditional lead-acid batteries. They provide consistent power throughout the charge cycle, ensuring that the pallet mover maintains its performance until it needs recharging. The battery is strategically placed within the frame to ensure balanced weight distribution, enhancing stability during operation. Most models feature a battery level indicator, allowing operators to monitor power usage and plan recharges to avoid unexpected downtime. Some pallet movers also support opportunity charging, enabling quick top-ups during breaks to extend operational time, which is especially useful in multi-shift operations. The operation of a pallet mover electric is user-friendly, making it accessible to operators of all skill levels. It is controlled via a tiller handle located at the rear, which includes buttons for moving forward, backward, lifting, and lowering the forks. The tiller handle is ergonomically designed with a comfortable grip to reduce hand and wrist fatigue during extended use. When the handle is tilted, the pallet mover moves in the corresponding direction, and releasing the handle engages the brake, ensuring immediate stopping. This intuitive control system allows operators to maneuver with precision, even in tight spaces, improving efficiency and reducing the risk of accidents. Maneuverability is a key advantage of a pallet mover electric. Its compact size and tight turning radius enable it to navigate through narrow aisles, doorways, and crowded areas, making it ideal for use in warehouses with high-density storage and retail stores with limited backroom space. The small footprint also allows it to fit into elevators and small trucks, facilitating transportation between different areas of a facility or even between locations. The wheels are made from high-quality polyurethane, which provides a smooth ride over concrete floors, minimizes noise, and prevents damage to indoor surfaces. This makes the pallet mover electric suitable for use in noise-sensitive environments such as hospitals, schools, and office buildings. The lifting mechanism of a pallet mover electric is powered by an electric motor, eliminating the need for manual pumping required by traditional pallet movers. With the press of a button, the forks lift the pallet to a height sufficient to clear the ground—typically a few centimeters—allowing for easy transport. This electric lifting system reduces physical strain on operators, lowering the risk of musculoskeletal injuries and making the job more accessible to a wider range of workers. The lifting and lowering speeds are optimized for efficiency, reducing cycle times and increasing productivity. Safety features are integrated into the design of a pallet mover electric to protect operators, goods, and equipment. The automatic braking system engages when the tiller handle is released, preventing unintended movement and ensuring that the pallet mover comes to a stop quickly. Many models include a horn and LED lights to alert pedestrians and other workers to the pallet mover’s presence in busy areas, enhancing safety in shared workspaces. Overload protection systems prevent the pallet mover from lifting loads exceeding its rated capacity, reducing the risk of structural damage or tipping. The forks are designed with rounded edges to avoid damaging pallets or goods during handling, and the stable frame ensures that loads remain secure during transport. Maintenance of a pallet mover electric is straightforward, contributing to its long-term reliability and cost-effectiveness. Regular maintenance tasks include checking the battery connections for corrosion, inspecting the wheels for wear, and lubricating moving parts such as the mast and hinges. The electric motor and controller are designed for durability and require minimal maintenance beyond periodic cleaning. Lithium-ion batteries need no maintenance other than regular charging, while lead-acid batteries (if used) require occasional water refills to maintain proper electrolyte levels. This low maintenance profile reduces downtime and operational costs, making the pallet mover electric a practical choice for businesses. The applications of a pallet mover electric are diverse, spanning various industries. In e-commerce fulfillment centers, it is used to move pallets from storage racks to packing stations, streamlining order processing and reducing fulfillment times. In retail, it assists with restocking shelves from backrooms, allowing staff to focus on customer service rather than manual labor. In manufacturing, it transports raw materials to production lines and finished products to shipping areas, integrating seamlessly into production workflows. It is also useful in cold storage facilities, as its electric components can withstand low temperatures, making it suitable for food and beverage warehouses. Cost-effectiveness is a significant benefit of a pallet mover electric. While the initial purchase price is higher than that of a manual pallet mover, the labor savings and increased productivity quickly offset this difference. The electric operation eliminates the need for manual effort, reducing the time required to move loads and allowing operators to handle more tasks in a shift. Lower maintenance costs compared to internal combustion equipment and the elimination of fuel costs further enhance its affordability. Additionally, the reduction in workplace injuries associated with manual lifting leads to lower medical expenses and workers’ compensation claims, providing long-term cost savings. In conclusion, a pallet mover electric is a valuable investment for businesses looking to improve their material handling operations. Its efficient electric power, ergonomic design, maneuverability, and safety features make it a superior alternative to manual pallet movers. Whether used in a large warehouse or a small retail store, it enhances productivity, reduces labor costs, and creates a safer work environment, proving its worth as an essential piece of material handling equipment.