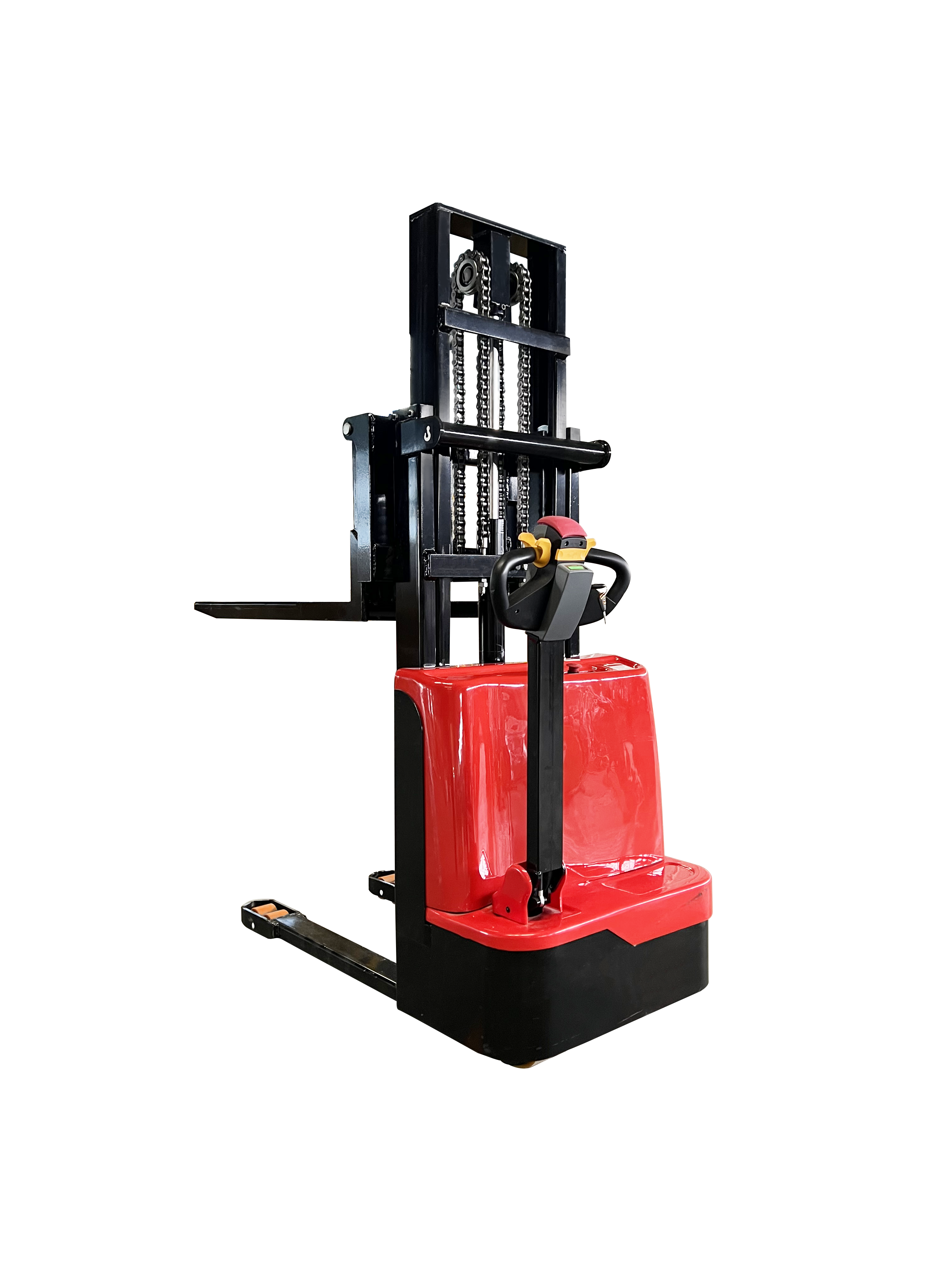

A pallet stacking truck, also known as a pallet stacker, is a specialized material handling vehicle designed to lift, transport, and stack palletized goods efficiently, bridging the gap between manual pallet jacks and full-sized forklifts. This versatile equipment is widely used in warehouses, distribution centers, retail stores, and manufacturing facilities, where it excels at maximizing vertical storage space and streamlining the movement of pallets in tight or narrow areas. Unlike forklifts, which are larger and more suited for heavy-duty lifting and outdoor use, a pallet stacking truck is compact, maneuverable, and focused on pallet-specific tasks, making it an essential tool for businesses looking to optimize their storage and material handling processes without the need for bulky equipment. The design of a pallet stacking truck is centered around its ability to lift pallets to elevated heights and move them with precision. It features a set of steel forks that slide under pallets, a lifting mechanism—either manual, hydraulic, or electric—and a control system that allows the operator to maneuver the truck and adjust the fork height. The lifting capacity of a pallet stacking truck typically ranges from 1,000 kg to 3,000 kg, with lifting heights varying from 1.5 meters for low-level stacking to 6 meters or more for high-rack storage, depending on the model. This range makes it suitable for a variety of applications, from stacking pallets on low shelves in retail backrooms to accessing high racks in large warehouses. One of the key advantages of a pallet stacking truck is its maneuverability, which is critical in environments where space is limited. Most models are designed with a compact footprint, allowing them to navigate through narrow aisles—some as narrow as 1.2 meters—and tight corners, making it possible to access pallets stored in areas that would be inaccessible to larger forklifts. Many pallet stacking trucks feature a three-wheel design, with the rear wheel or wheels capable of swiveling, providing a tight turning radius that enhances agility. This maneuverability not only improves efficiency by reducing the time needed to move pallets but also minimizes the risk of damage to pallets, goods, or warehouse infrastructure, such as racks or walls. Pallet stacking trucks are available in several configurations, each tailored to different operational needs and workloads. Manual pallet stacking trucks require the operator to pump a lever to lift the forks, making them suitable for light-duty applications with low throughput, such as small retail stores or workshops. They are cost-effective and require minimal maintenance but can be physically demanding for operators, especially when lifting to higher heights. Hydraulic pallet stacking trucks use a hydraulic pump—either manual or powered by an electric motor—to lift loads more easily, reducing operator effort and increasing efficiency for medium-duty operations. They offer a balance between cost and performance, making them popular in medium-sized warehouses and distribution centers. Electric pallet stacking trucks, powered by rechargeable batteries, are the most advanced option, featuring electric lifting and propulsion systems that eliminate manual effort entirely. These models are ideal for high-throughput environments, offering faster lifting and movement speeds, longer operating times, and reduced operator fatigue. They are particularly well-suited for indoor use, as they produce zero emissions and operate quietly, making them suitable for environments where air quality or noise is a concern, such as food processing facilities, hospitals, or retail stores. Safety is a critical aspect of any pallet stacking truck, with numerous features designed to protect operators, goods, and the surrounding area. The forks are engineered to securely hold pallets, with many models featuring a locking mechanism that keeps the forks at a set height to prevent accidental lowering. Overload protection systems are common, preventing the truck from lifting loads that exceed its rated capacity, which reduces the risk of tip-overs or structural damage. The operator’s position is designed for visibility, with a clear line of sight to the forks and the surrounding environment, helping to avoid collisions with other equipment, personnel, or warehouse structures. Many models also include emergency stop buttons, non-slip platforms, and warning devices such as horns or lights to alert others to the truck’s presence in busy areas. Versatility is a standout feature of a pallet stacking truck, with options and attachments that allow it to adapt to a wide range of applications. Adjustable fork widths enable it to handle different pallet sizes, from standard 1200x1000mm pallets to smaller or larger custom pallets, making it suitable for diverse industries, including retail, logistics, manufacturing, and pharmaceuticals. Some models offer a tilting fork function, which allows the forks to tilt slightly to prevent goods from sliding off during transport, which is particularly useful for handling unstable or irregularly shaped loads. In cold storage environments, specially designed pallet stacking trucks with cold-resistant components can operate reliably at low temperatures, making them suitable for frozen food warehouses or pharmaceutical storage facilities. The operational benefits of a pallet stacking truck are numerous, contributing to improved efficiency and cost savings in material handling operations. By enabling pallets to be stacked vertically, it maximizes the use of available storage space, reducing the need for additional warehouse square footage and lowering rental or construction costs. The truck’s maneuverability reduces the time needed to move and stack pallets, increasing throughput and allowing staff to focus on other tasks, such as order picking or inventory management. For electric models, the elimination of manual effort reduces operator fatigue and the risk of workplace injuries, lowering healthcare costs and workers’ compensation claims. Maintenance requirements for pallet stacking trucks are relatively low compared to larger equipment like forklifts, with manual and hydraulic models requiring periodic checks of moving parts, lubrication, and hydraulic fluid levels. Electric models need battery maintenance—such as regular charging and occasional inspections—and checks of the electric motor and controls. This low maintenance profile minimizes downtime and keeps