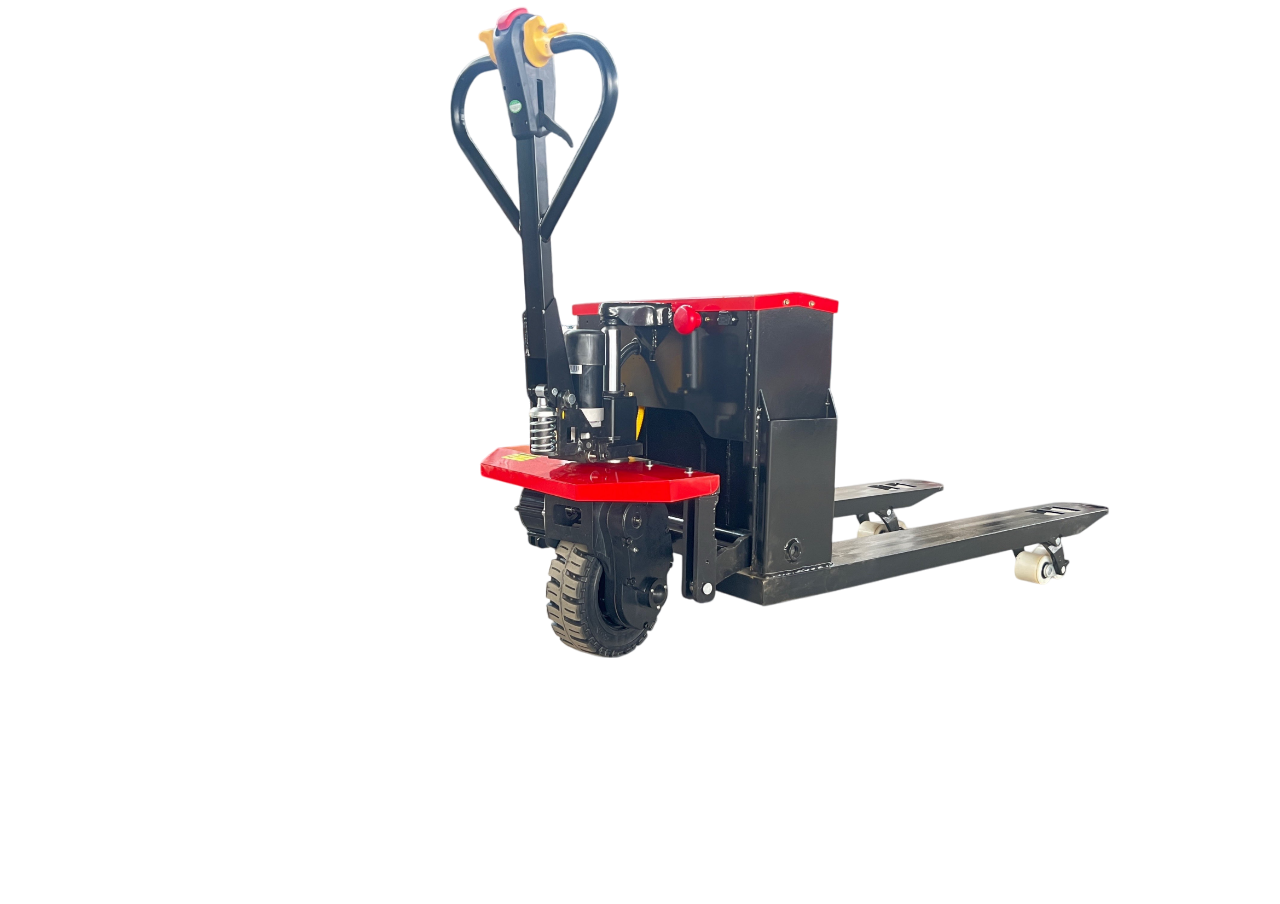

An electric pallet truck is a game-changer in material handling, designed to simplify the transportation and lifting of palletized goods through electric power, offering a significant upgrade from manual alternatives. It is widely used in warehouses, distribution centers, retail stores, and manufacturing facilities, providing a perfect blend of efficiency, power, and ease of operation. This equipment is essential for businesses looking to reduce manual labor, increase productivity, and create a safer work environment, all while maintaining cost-effectiveness. The construction of an electric pallet truck is robust, with a durable steel frame that ensures longevity even with daily heavy use. The frame is designed to withstand the weight of heavy loads, typically ranging from 1,500 kg to 3,000 kg, and resist damage from accidental impacts with racks, walls, or other equipment. The forks, made from high-grade steel, are engineered to slide smoothly under pallets and remain stable during lifting and transport. They are usually spaced to fit standard pallet dimensions, but many models offer adjustable fork widths to accommodate various pallet sizes, enhancing versatility across different applications. The driving force behind an electric pallet truck is its electric motor, powered by a rechargeable battery—most commonly lead-acid or lithium-ion. Lithium-ion batteries are gaining popularity due to their faster charging times, longer lifespan, and lighter weight compared to lead-acid batteries. They provide consistent power throughout the charge cycle, ensuring that the truck maintains its performance until it needs recharging. The battery is typically located under the operator’s platform or within the frame, contributing to the truck’s balanced weight distribution and stability. Many electric pallet trucks feature battery level indicators, allowing operators to monitor power usage and plan recharges to avoid unexpected downtime. Some models also support opportunity charging, enabling quick top-ups during breaks to extend operational time. The operation of an electric pallet truck is intuitive, making it easy for operators to learn and use. It is controlled via a tiller handle located at the rear, which includes buttons or levers for moving forward, backward, lifting, and lowering the forks. The tiller handle is ergonomically designed with a comfortable grip to reduce hand fatigue during extended use. When the handle is tilted, the truck moves in the corresponding direction, and releasing it engages the brake, ensuring immediate stopping. This responsive control system allows operators to maneuver with precision, even in tight spaces. Maneuverability is a key advantage of an electric pallet truck. Its compact size and tight turning radius enable it to navigate through narrow aisles and crowded areas, making it ideal for warehouses with high-density storage. The small footprint also allows it to fit into elevators and small trucks, facilitating transportation between locations. The wheels are made from high-quality polyurethane or rubber, which provide a smooth ride over concrete floors, minimize noise, and prevent damage to indoor surfaces. This makes the electric pallet truck suitable for use in retail environments, where quiet operation and floor protection are important. Safety features are integrated into the design of an electric pallet truck to protect operators, goods, and equipment. The automatic braking system engages when the tiller handle is released, preventing unintended movement. Many models include a horn and lights to alert others to the truck’s presence in busy areas. The forks are designed with rounded edges to avoid damaging pallets or goods during handling. Some advanced models feature overload protection, which stops the lifting mechanism if the load exceeds the truck’s rated capacity, reducing the risk of structural damage or tipping. The low center of gravity and stable frame further enhance safety, even when carrying heavy loads. Maintenance requirements for an electric pallet truck are relatively low compared to internal combustion equipment. With fewer moving parts than gas or diesel-powered trucks, there is less wear and tear, and no need for oil changes, fuel filters, or exhaust system maintenance. Regular maintenance tasks include checking battery connections for corrosion, inspecting tires for wear, and lubricating moving parts such as the mast and hinges. Cleaning the truck regularly to remove dirt and debris helps prevent rust and ensures optimal performance. Lithium-ion batteries require minimal maintenance, while lead-acid batteries need periodic water refills to maintain proper electrolyte levels. This low maintenance profile reduces operational costs and downtime, contributing to the truck’s cost-effectiveness. The applications of an electric pallet truck are diverse, spanning various industries. In warehouses and distribution centers, it is used to move pallets between storage racks, loading docks, and sorting areas, streamlining inventory management. In retail, it assists with restocking shelves from storage rooms, allowing staff to efficiently transport merchandise without disrupting customers. In manufacturing facilities, it transports raw materials to production lines and finished products to storage or shipping areas. It is also useful in cold storage environments, as its electric components can withstand low temperatures, making it suitable for food and beverage warehouses or pharmaceutical facilities. The quiet operation of an electric pallet truck makes it ideal for noise-sensitive environments, such as hospitals, schools, and office buildings with attached warehouses. It can be used during regular business hours without causing disturbances, unlike noisy gas or diesel-powered equipment. This flexibility in operating hours helps businesses maximize productivity by utilizing off-peak times for material handling tasks. Cost-effectiveness is a significant benefit of investing in an electric pallet truck. While the initial purchase price is higher than that of a manual pallet jack, the time and labor savings quickly offset this difference. Electric pallet trucks reduce the physical strain on operators, lowering the risk of workplace injuries and associated costs. They also increase productivity by allowing operators to move heavier loads more quickly than manual alternatives. The lower operating costs compared to gas or diesel-powered trucks—due to cheaper electricity and reduced maintenance—further enhance their economic value over time. In conclusion, an electric pallet truck is an indispensable tool for modern material handling operations. Its efficient electric motor, intuitive controls, maneuverability, and safety features make it a reliable and cost-effective solution for businesses of all sizes. Whether used in a large warehouse or a small retail store, it improves productivity, enhances workplace safety, and contributes to a healthier, quieter work environment. As battery technology continues to advance, electric pallet trucks will only become more efficient and versatile, solidifying their role as a cornerstone of efficient material handling.