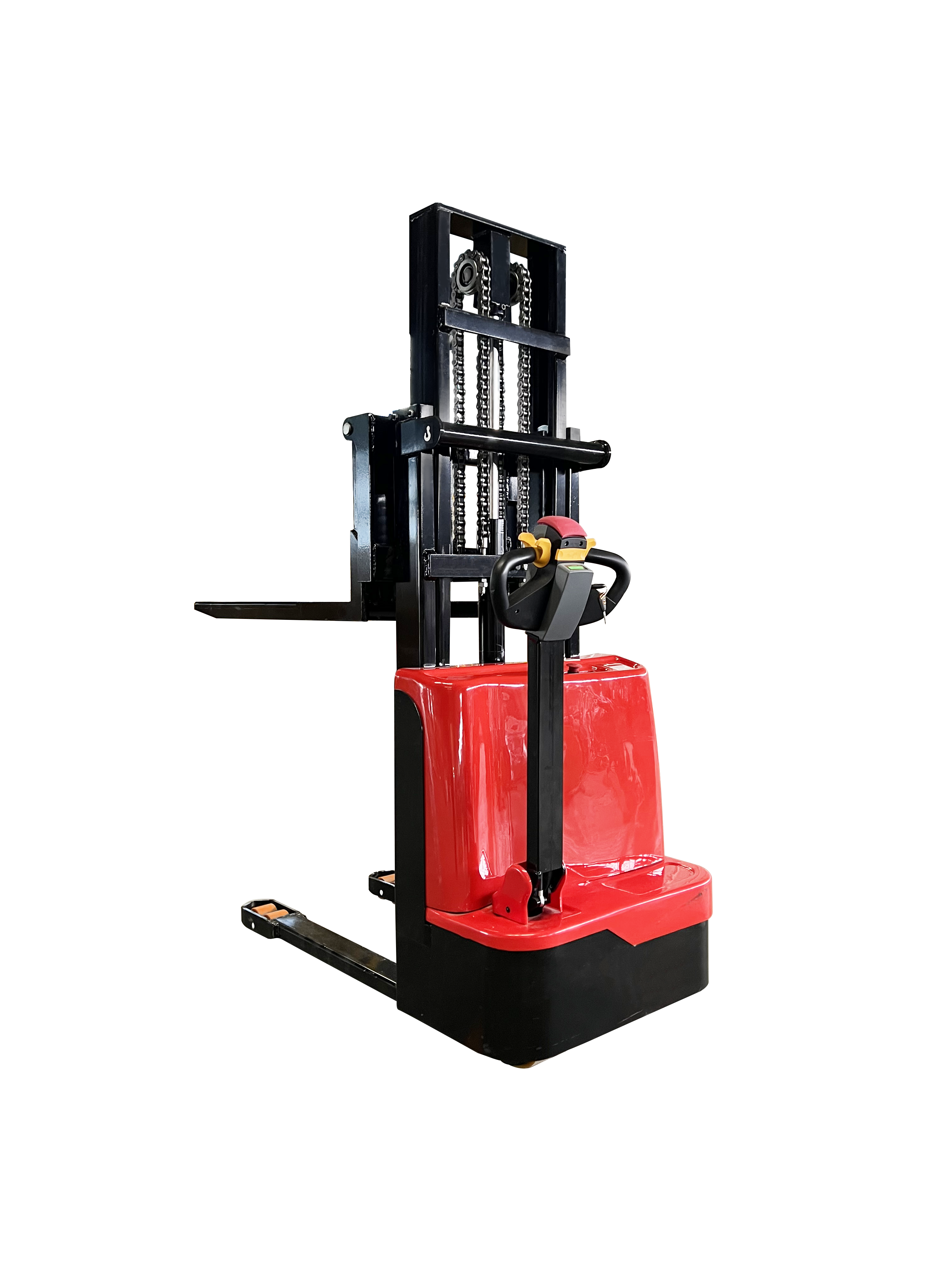

An electric straddle stacker is a specialized material handling equipment designed to lift, transport, and stack palletized goods with precision, featuring a unique straddle base that provides exceptional stability when handling loads. Unlike standard pallet stackers, it has two extended legs (or straddles) that extend beyond the forks, allowing it to straddle wider loads or pallets that are not perfectly aligned, making it ideal for handling irregularly shaped items or open-bottom pallets. Powered by electricity, this stacker offers a clean, quiet, and efficient solution for warehouses, distribution centers, manufacturing facilities, and retail environments where stability, maneuverability, and versatility are essential. The core design of an electric straddle stacker revolves around its straddle base, which consists of two sturdy steel legs positioned on either side of the forks. These legs distribute the weight of the load evenly, enhancing stability, especially when lifting to higher heights or handling unevenly distributed loads. The legs can be adjusted in width on some models, allowing the stacker to accommodate different pallet sizes or load widths, from narrow crates to wide machinery components. This adjustability makes the electric straddle stacker highly versatile, capable of handling a broader range of load types than standard stackers, which is particularly valuable in industries with diverse inventory, such as manufacturing or retail. The lifting mechanism of an electric straddle stacker is powered by an electric motor, driven by a rechargeable battery—typically lithium-ion for its superior performance, including faster charging, longer runtimes, and a longer lifespan compared to lead-acid batteries. The motor drives a hydraulic pump that raises and lowers the forks, enabling smooth and precise elevation to heights ranging from 2 meters to 5 meters, depending on the model. This electric-powered lifting eliminates the need for manual pumping, reducing operator fatigue and allowing for consistent performance throughout the workday. The battery also powers the propulsion system, which allows the stacker to move forward and backward at adjustable speeds, with most models reaching up to 5 km/h, ensuring efficient movement across the workspace. Maneuverability is a key advantage of an electric straddle stacker, despite its straddle base. While the legs add some width, the overall design remains compact enough to navigate through narrow aisles—typically as narrow as 2 meters—making it suitable for warehouses with high-density storage. The stacker is equipped with durable wheels, often made of polyurethane for smooth operation on concrete floors, with the rear wheels featuring a swivel design to provide a tight turning radius. This allows operators to maneuver easily around obstacles, between racks, and into tight corners, ensuring that even large or irregular loads can be positioned with precision. Operator comfort and safety are prioritized in the design of an electric straddle stacker. The control handle is ergonomically designed with a comfortable grip and intuitive buttons for lifting, lowering, and moving the stacker, reducing hand and wrist strain during extended use. Many models feature a fold-down platform for the operator to stand on during longer moves, eliminating the need to walk alongside the stacker and reducing fatigue. Safety features include overload protection, which prevents the stacker from lifting loads exceeding its rated capacity (typically between 1,000 kg and 3,000 kg), reducing the risk of tip-overs. Emergency stop buttons are prominently located on the control handle and chassis, allowing for immediate shutdown in case of an emergency. The straddle legs themselves act as a safety barrier, preventing the load from shifting sideways and protecting the operator from potential collisions with the load. The electric straddle stacker excels in handling specific load types that standard stackers may struggle with. Open-bottom pallets, which lack the solid base of closed pallets, are easily managed by the straddle legs, which support the load from the sides, preventing it from sagging or falling. It is also ideal for handling drums, barrels, or large boxes that are not palletized, as the straddle legs can secure these items while the forks provide additional support. In manufacturing facilities, it is often used to move heavy machinery components or work-in-progress items between production stations, where stability is critical to avoid damage to expensive equipment. In retail, it can handle large appliances or furniture, which are often shipped on irregularly shaped pallets or crates. One of the primary benefits of an electric straddle stacker is its cost-effectiveness. While the initial purchase price may be higher than that of a standard electric stacker, its versatility reduces the need for multiple pieces of equipment, lowering overall investment costs. The electric operation minimizes ongoing expenses, as electricity is cheaper than fuel, and maintenance requirements are low—no oil changes, fuel filters, or exhaust system repairs are needed. Lithium-ion batteries require minimal maintenance beyond regular charging, further reducing operational costs. Additionally, the stacker’s efficiency and speed increase productivity, allowing operators to handle more loads in less time, which translates to lower labor costs over time. Environmental considerations are another advantage of the electric straddle stacker. Its electric motor produces zero emissions, making it safe for indoor use without concerns about air quality or ventilation, which is particularly important in enclosed warehouses or retail backrooms. It operates quietly, with noise levels typically below 70 decibels, creating a more pleasant work environment and allowing for use during early mornings, evenings, or in noise-sensitive areas such as residential neighborhoods or office buildings adjacent to warehouses. This aligns with the growing trend toward sustainable business practices, helping companies reduce their carbon footprint and meet environmental regulations or certifications. When selecting an electric straddle stacker, it is important to consider factors such as load capacity, lifting height, leg width adjustability, and battery type to ensure it meets specific operational needs. For facilities with high throughput, a model with a larger battery and faster charging capabilities is ideal to minimize downtime. For those handling a wide range of load sizes, adjustable leg widths are a must. Testing the stacker with typical loads and in the actual workspace can help verify its maneuverability and stability, ensuring it performs as expected. Training operators on proper use, including adjusting leg widths, handling irregular loads, and battery maintenance, is essential to maximize safety and efficiency. In conclusion, an electric straddle stacker is a versatile, efficient, and safe material handling solution that excels in handling a wide range of loads, particularly irregularly shaped or open-bottom items. Its unique straddle base provides superior stability, while its electric power ensures clean, quiet operation. With its maneuverability, adjustability, and cost-effectiveness, it is an invaluable asset for warehouses, manufacturing facilities, and retail environments looking to optimize their material handling processes, enhance productivity, and reduce operational costs. As businesses continue to seek more flexible and sustainable equipment, the electric straddle stacker stands out as a smart investment that delivers long-term value.