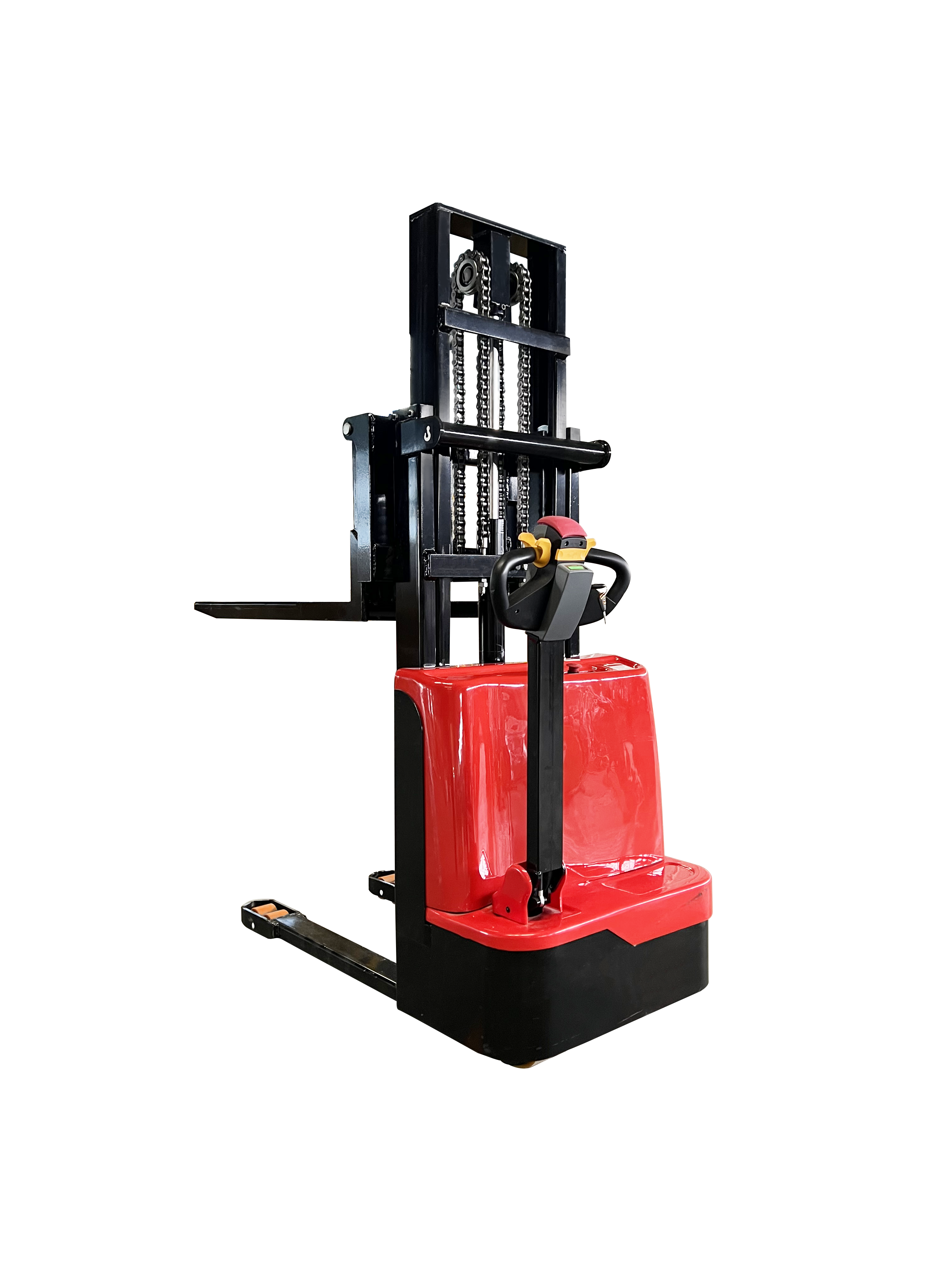

Hydraulický paletový stohovač je robustní zařízení pro manipulaci s materiály navržené pro zvedání, přepravu a stohování paletovaných zboží pomocí hydraulické energie, které nabízí spolehlivou rovnováhu pevnosti, účinnosti a cenové dostupnosti pro širokou škálu průmyslov Tento všestranný nástroj se široce používá ve skladech, distribučních centrech, maloobchodních zádech a výrobních zařízeních, kde vyniká při přesunu středních až těžkých nákladů v vnitřním i vnějším prostředí. Díky využití hydraulického tlaku k zvedání nákladů snižuje manuální úsilí, zvyšuje produktivitu a poskytuje stabilní výkon, což z něj dělá populární volbu pro podniky, které hledají nákladově efektivní alternativu plně elektrickým stohovačům nebo velkým vysokozdvižným vozíkům. Jádrová funkce hydraulického palletového stohovače závisí na hydraulickém systému, který se skládá z čerpadla, válce a hydraulické kapaliny. Když obsluha pumpy připraví ručně pomocí páky nebo automaticky pomocí elektrického motoru, je hydraulická tekutina pod tlakem a tlačena do válce, což způsobuje, že píst prodlouží a zvedne vidličky. Tento mechanismus umožňuje hladké a řízené zvedání nákladů do výšek od 1,5 do 5 metrů v závislosti na modelu, přičemž zvedávací kapacity se obvykle pohybují mezi 1 000 kg a 3 000 kg. Při snížení zatížení se hydraulický tlak postupně uvolňuje, což zajišťuje, že vidličky se pomalu a bezpečně sníží, čímž se zabrání poškození zboží nebo samotného stohovače. Tento hydraulický systém je známý svou odolností a schopností zvládat těžké zatížení, a to i v náročných prostředích. Hydraulické paletové stohovače jsou k dispozici ve dvou hlavních konfiguracích: ruční a poloelektrické. Ruční hydraulické stohovače vyžadují, aby obsluha pumpovala páku k aktivaci hydraulického systému a zvedání zatížení, zatímco pohyb stohovače (předem a dozadu) se provádí ručně tlačením nebo tažením. Tyto modely jsou ideální pro lehké až středně velké aplikace s nízkým výkonem, jako jsou malé maloobchodní prodejny, dílny nebo sklady s omezeným prostorem. Jsou cenově dostupné, vyžadují minimální údržbu a jsou snadno ovladatelné, což je činí dostupnými pro podniky s omezeným rozpočtem nebo příležitostným používáním. Polovečerní hydraulické stohovače kombinují ruční hydraulické zvedání s elektrickým pohonem, což umožňuje obsluze pohybovat stohovač pomocí ovládací rukojeti s tlačítky pro pohyb vpřed a dozadu. To snižuje fyzickou námahu potřebnou k přepravě nákladů na větší vzdálenosti, což je činí vhodnými pro středně velké a velké operace, jako jsou středně velké sklady nebo distribuční centra. Elektrický pohon je poháněn nabíjecí baterií, obvykle olověnou (i když se stávají běžnějšími lithium-iontové možnosti), což poskytuje dostatek času na plnou pracovní směnu. Jednou z hlavních výhod hydraulického palletového stohovače je jeho všestrannost při manipulaci s různými typy nákladů a prostředí. Na rozdíl od plně elektrických stohovačů, které mohou být omezeny na použití v interiéru kvůli omezení baterií, mohou být hydraulické stohovače, zejména manuální modely, používány venku v suchých podmínkách, protože nejsou závislé na elektřině a jejich hydraulické systémy jsou relativně odolné Díky tomu jsou užitečné pro nakládání a vykládání nákladních vozidel ve venkovních dokách nebo pro přesun palet mezi vnitřním skladem a venkovními prostory. Díky pevné konstrukci a většímu počtu kol v některých těžkých verzích jsou také schopny zvládat nerovné nebo drsné povrchy lépe než některé elektrické modely. Hydraulický paletový stohovač je navržen tak, aby byl stabilní, s širokou základnou a nízkým těžištěm, které minimalizují riziko převrácení, a to i při zvedání těžkých nákladů na maximální výšky. Vidličky jsou vyrobeny z vysoce pevné oceli, často s nastavitelnými šířkami pro různé velikosti palet, od standardních palet o velikosti 1200x1000 mm až po menší bedny nebo větší průmyslové palety. Některé modely mají skládací design, který jim umožňuje kompaktní skladování, když nejsou v provozu, což je cenné pro podniky s omezeným skladovacím prostorem pro zařízení. Řidičová rukojeť je ergonomicky navržena s pohodlným uchopem a intuitivními ovládacími prvky, které snižují únavu obsluhy při delším používání, a to i při ručním čerpání. V hydraulických paletových sklápěčích jsou integrovány bezpečnostní prvky, které chrání provozovatele a zabraňují nehodám. Přetížení ventily zabraňují stackeru zvednout zatížení, které přesahuje jeho jmenovitou kapacitu, a zajistí, aby hydraulický systém a konstrukční komponenty nebyly poškozeny. Mnoho modelů obsahuje bezpečnostní řetězec nebo zámek, který upevňuje vidličky v zvednuté poloze, čímž se brání náhodnému snížení, pokud hydraulický systém ztratí tlak. Vidličky jsou na okraji zaoblené, aby se zabránilo poškození palet nebo zboží při vložení, a základna je navržena tak, aby se zabránilo nakládači naklonit dopředu, když jsou vidličky prodlouženy. Některé poloelektrické modely obsahují tlačítka nouzového zastavení a varovné buňky, které upozorňují ostatní na přítomnost stojáka v rušných oblastech. Údržba hydraulického palletového stohovače je jednoduchá, což přispívá k jeho dlouhé životnosti a spolehlivosti. Mezi pravidelné údržby patří kontrola hladiny hydraulické kapaliny a zajištění její čistoty a bez kontaminace. Špinavá kapalina může poškodit čerpadlo a válce, což může vést ke snížení výkonu nebo únikům. Hydraulické hadice a těsnění by měly být zkontrolovány na trhliny nebo úniky a okamžitě nahrazeny, aby se zabránilo ztrátě tekutiny. K zajištění hladkého provozu by měly být pohyblivé části, jako jsou kolíky a kolíky vidliček, pravidelně mazány. U poloelektrických modelů vyžaduje baterie pravidelné nabíjení a v případě olověných baterií je třeba příležitostně doplňovat vodu, aby byla udržena správná hladina elektrolytů. Pravidelné čištění zásobníku, aby se odstranil nečistoty, prach a fragmenty palety, pomáhá zabránit hrudě a zajistí, aby všechny součásti fungovaly správně. Výrobní náklady jsou významnou výhodou hydraulických paletových stackérů, zejména ručních modelů, které mají nižší počáteční nákupní cenu ve srovnání s plně elektrickými stackery. To je činí atraktivní volbou pro malé podniky nebo začínající podniky s omezeným rozpočtem, které jim umožňují zlepšit účinnost manipulace s materiály bez velkých investic. Náklady na údržbu jsou také nízké, protože nejsou k opravě žádné složité elektrické motory nebo řídicí systémy. Zatímco poloelektrické modely mají vyšší náklady než manuální, jejich elektrický pohon snižuje únavu obsluhy a zvyšuje produktivitu, což vede k dlouhodobému úsporě nákladů na pracovní sílu. Hydraulické paletové stohovače jsou široce používány v různých odvětvích, z nichž každá těží z jejich jedinečných schopností. V maloobchodu se manuální modely používají k přesunu zásob z zadního skladu do prodejních podlaží, kde jejich kompaktní velikost a snadné použití je činí ideálními pro navigaci v těsných prostorách. V výrobě přepravují poloelektrické modely suroviny na výrobní linky a hotové výrobky do přepravních oblastí, které zvládnou těžší zatížení běžné v průmyslových prostředích. V logistice se používají k nakládání a vykládání palet z nákladních vozidel a tak překonávají propast mezi dokem a skladem. V zemědělství pomáhají s přemístěním bedn produktů nebo krmiv, a to jak uvnitř, tak i venku, díky své odolnosti. Výsledkem je, že hydraulický palletový stohovač je praktické, spolehlivé a nákladově efektivní řešení pro potřeby manipulace s materiály, které nabízí rovnováhu mezi pevností, všestranností a snadným používáním. Ať už je ručně nebo poloelektrický, vyniká v zvedání a přepravě těžkých nákladů v různých